Property Loss Recovery

Once any critical loss mitigation measures have been completed, work on recovering property can begin. Many items can be recovered, provided they are not irreparably damaged by the incident: buildings and facilities, machinery and production lines, precision CNC machines, electrical power generation and distribution equipment, electronics, and even documents and data media.

The services offered by traditional service providers, such as construction companies and equipment suppliers (for replacement solutions) and cleaning companies (for simple cleaning solutions) are usually not aligned to a disaster situation. For this reason, these traditional service providers are unlikely to deliver an effective time and cost solution.

That’s where BELFOR Asia comes in. We develop customised solutions for every disaster situation to recover property within the shortest time, and at the lowest possible cost.

Benefits of Recovery

Replacing sophisticated equipment or rebuilding facilities often takes a long period of time to complete. Business interruption can result in the loss of valuable contracts and clients. In comparison, our recovery projects can be completed within days or a few weeks, significantly limiting business interruption and minimising financial losses.

In addition, the price of our recovery services is typically only 10-40% of the replacement cost of the property, providing significant property reinstatement cost savings.

Our Strengths

There are 6 key reasons why we excel at what we do:

- Our people. They are our most valuable asset. Qualified and fully-trained in our proprietary recovery processes, our recovery specialists typically come with 10 and in some cases more than 20 years of experience.

- Our processes. We have developed and documented more than 60 recovery processes at our R&D centre in Munich, Germany. For every disaster incident, we carefully conduct a damage assessment, before selecting and implementing the most technically suitable and time-and-cost effective process.

- Our solutions. Over the past 35 years, through our R&D centre in Munich, Germany, we have developed and refined a complete range of cleaning agents for the decontamination of buildings, machinery and equipment.

- Our resources. We have a large inventory of equipment and tools strategically located in 9 countries within the East Asian region. Within 24 hours, complete sets of equipment can be simultaneously deployed to multiple locations.

- Our quality. Good isn’t good enough for us. Our detailed work procedures and integrated quality assurance systems ensure that we meet and exceed expectations.

- Our global network. Responsive local teams coordinate closely with regional and worldwide teams to respond swiftly to emergencies, wherever they may be.

Buildings and Facilities

Disaster incidents often cause widespread contamination of buildings and industrial facilities. Once loss mitigation measures have been implemented, we act swiftly to bring the facility back to a condition fit for purpose.

Our strengths are the expertise of our Restoration Specialists to determine optimum recovery processes. Teams of supervisors are rapidly mobilised to work with our clients own people or local contract labour, to carry out the recovery work.

We provide equipment required for working at elevated heights, and train all personnel involved in safety procedures.

We also provide all chemicals and equipment required for the decontamination process.

The project is managed and closely supervised by BELFOR personnel. We verify that all surfaces of the facility have been treated and comply with the agreed cleanliness standards.

There is no faster way to bring you back to business.

Machinery and Production Lines

Machinery and production lines are the life-line for manufacturers worldwide. When disaster strikes, machinery and production lines often become contaminated, bringing production to a halt.

Due to the initial appearance of the property after a disaster, and lacking experience in such circumstances, the original equipment manufacturers will usually propose replacement.

In contrast, BELFOR has recovery processes which will bring disaster affected equipment rapidly back to power-on testing condition. We have the strength to bring all necessary project resources to site within 1-2 days. This capability is not available from the original equipment manufacturer.

Without us, you may face a single option based on replacement, with the resulting long business interruption period. With our involvement, we will provide you with a second option, involving a shorter period of business interruption.

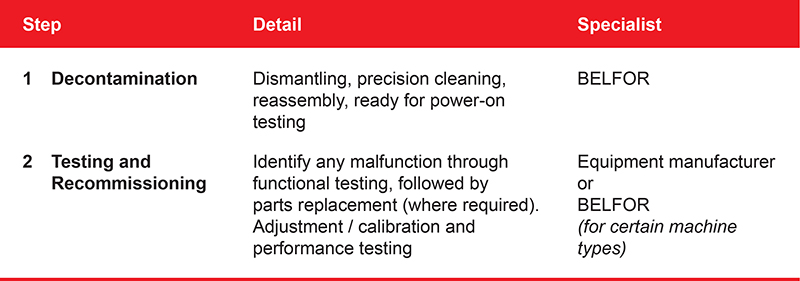

How We Work

Marine and Offshore

Ships and offshore platforms can be affected by contamination from fire, fresh water or salt water ingress.

Our Expertise

We are frequently engaged to provide decontamination services related to:

- Engine Rooms

- Diesel Generators

- Engine Control Rooms

- Bow Thruster Compartments

- Bridge

- Galleys

These areas contain high value items such as low and medium voltage switchgear, diesel generators, transformers, main engines, pumps, electrical control cubicles, and variable frequency motor drives, which are critical to operations.

We have worked on ships and offshore platforms in Korea, China, Hong Kong, Japan and Singapore, and occasionally at overseas ports where incidents occurred, such as Fiji and Australia. Occasionally, our project teams worked on board affected vessels while en-route to the next port.

Semiconductor

Semiconductor manufacturing processes are characterised by the extensive use of toxic and hazardous chemicals within extremely clean environments. When equipment defects or operator errors occur, the outcome can be the release of corrosive contaminants, or even fire.

Our Expertise

In collaboration with our Technical Support Department in Munich, Germany, we have developed decontamination processes for use in these ultra clean high tech environments.

We have carried out disaster recovery work on the complete range of tools and equipment utilised in semiconductor fabrication, assembly and testing processes.

BELFOR is the only disaster recovery service provider with a proven track record in this industry.

Power Generation and Distribution

Power generation and distribution equipment transmits large amounts of electrical energy through multiple connections, while remaining insulated from ground. There is always the potential for failure due overheating of bolted connections or degradation of insulation.

Failure incidents often involve smoke or fire, and resulting equipment contamination and service outage, temporarily crippling manufacturing or service operations.

How we work

We are able to mobilise recovery teams within hours to commence recovery of equipment. As this equipment is usually vital for the organisation concerned, we utilise safe and time effective solutions, to minimise interruptions.

Our Expertise

We are skilled in the recovery of generators (diesel/steam/hydroelectric/gas turbine), transformers (dry resin and oil cooled), low, medium and high voltage switchgear, circuit breakers (air/vacuum/oil/and gas insulated switches (e.g. sulphur hexafluoride) and control cubicles.

We have carried out recovery work on power station equipment in Bangladesh, India, the Philippines, China, Taiwan, and Thailand.

Electronics

We have the most well developed electronics recovery expertise in the world. Using proprietary chemicals and innovative methods developed within our own R&D laboratories in Munich, Germany, our recovery processes have been tested and approved by several major manufacturers of electronic equipment.

In strict compliance with industry specifications, we have successfully recovered electronic equipment exposed to corrosive soot from fires, flood water, dust from explosions, acid vapours, mould, and many other types of contamination.

Our expertise has been applied to a wide range of electronic equipment across many industries, including:

- Computers and servers

- Telecommunications equipment

- Semiconductor front and back end manufacturing equipment

- Scientific and laboratory equipment

- Control systems in nuclear and other power systems

- Aviation and satellite control systems

- Pharmaceutical and food production equipment

- Control electronics in locomotives and ships

- Audio and video equipment

Documents and Data

Disaster incidents can cause documents to become wet or soiled and electronic data files to become damaged or lost. We have proven processes to help you recover from these incidents.

Our Expertise

Recovery of wet documents

Our new generation of vacuum freeze dryers and thermal vacuum freeze dryers are specifically-designed to fully dry and recover documents, books and paper materials.

Recovery of lost data

We have teamed up with leading providers of data recovery services throughout the world to ensure that, where possible, every byte of lost data is found.